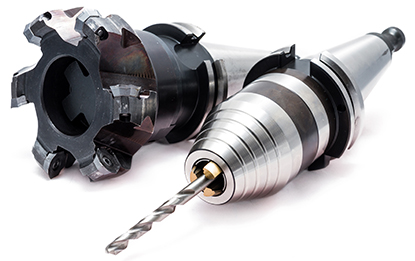

This is Precision

Since 2005, GLC has been an integral and seamless extension of our customers’ machining, turning, milling, and robotic welding operations. With unmatched quality and competitive pricing, we boost bottom line returns and increase productivity across the enterprise.

We handle the most complex product specifications to meet the highest consumer expectations – a true partner in success. Precision and value are the heartbeat of GLC.